There’s one big question when it comes to choosing the first saw for your shop. Should it be a table saw, or a bandsaw? It’s something woodworkers can get quite heated about!

I would definitely get a table saw eventually, but for me it’s a bandsaw first. The big advantage with bandsaws is their versatility. They can handle a wide range of tasks from ripping long boards to cutting angles and complex curves. If all you do is saw sheet material and boards, cutting in straight lines, then you’re probably better off with a table saw. If you want to get creative with your woodworking then a bandsaw is the tool for you.

OK. Let’s back up that comment by exploring what makes the best bandsaws so special.

So What Is A Bandsaw And How Does It Work?

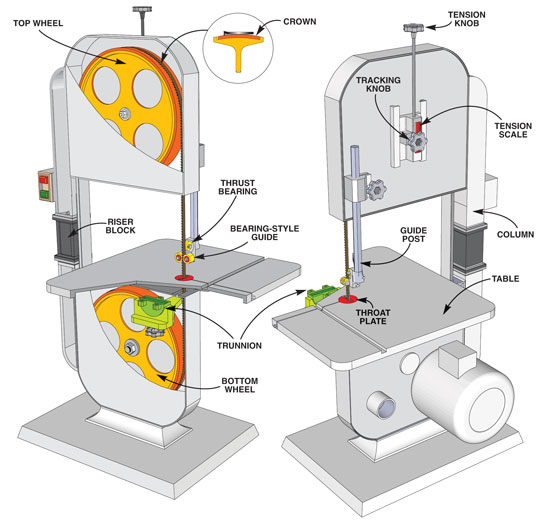

Feel free to jump on down a bit if you know all this, but I thought it was worth covering for beginner bandsaw users. The image I’ve used here is representative of most woodworking bandsaws and includes all the key components. Riser blocks aren’t always fitted. Thrust bearings are more commonly known as blade guides.

Feel free to jump on down a bit if you know all this, but I thought it was worth covering for beginner bandsaw users. The image I’ve used here is representative of most woodworking bandsaws and includes all the key components. Riser blocks aren’t always fitted. Thrust bearings are more commonly known as blade guides.

So, picture a continuous steel band with teeth along one edge. It wraps around upper and lower wheels with a table in between. A motor is attached to the lower wheel, driving the blade round. The part of the blade that does the cutting is always moving downwards. It’s safer that way because it doesn’t try to lift the workpiece up off the table. Upper and lower blade guides keep the blade running true.

Bandsaw blades are mostly designed to cut wood but can also cut through plastic, composites, and even thin sheets of brass, copper, and aluminum. The tools I’m talking about here are woodworking bandsaws. There are specific bandsaws for steel and iron but that’s a whole different subject!

Bandsaw blades come in a range of widths. Wide for ripping boards, narrower for cutting curves. Most woodworkers end up wth a selection of at least 3 or 4. Bandsaw blades also have different numbers of teeth. As with any saw blade the more teeth you have, the smoother (but slower) the cut.

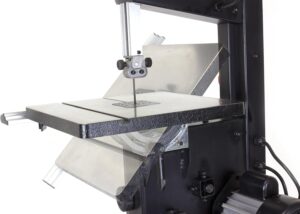

Bandsaws have an adjustable fence to help guide the workpiece in a straight line. They usually also have a miter guide for accurate angled cuts. The table can tilt at up to 45 degrees, so in combination with the miter guide it’s possible to cut compound angles. Fence and miter guide run in slots, and can be removed for freehand sawing, something that isn’t possible on a table saw.

Bandsaws have an adjustable fence to help guide the workpiece in a straight line. They usually also have a miter guide for accurate angled cuts. The table can tilt at up to 45 degrees, so in combination with the miter guide it’s possible to cut compound angles. Fence and miter guide run in slots, and can be removed for freehand sawing, something that isn’t possible on a table saw.

OK, so those are your bandsaw basics. There are a few more details to come but we’ll deal with those as we get to them.

Choosing The Right Bandsaw

Bandsaws come in a huge range of sizes from compact benchtop models to larger floor-standing machines. Here are some of the things you need to consider:

Cutting Capabilities

Bandsaws have two characteristics that define the size of the material you can cut. First is the maximum depth of cut. The upper blade guides on a bandsaw can be raised and lowered. Normally they’re adjusted close to the material so the blade doesn’t deflect and cause inaccuracies. There is a limit to the height they can be raised, so the distance between the table surface and the upper blade guides at their highest point defines the maximum depth of cut. Maximum thickness if you like.

Then there’s maximum width, which is defined by the distance between the blade where it cuts and the column at the back of the bandsaw where the blade runs through. This distance is usually called the throat.

Table Size & Material

Table Size & Material

The bigger the bandsaw table the more stable a platform you have for larger and longer workpieces. Table width is usually close to the throat size. Table length may be an inch or two more. Many bandsaw tables are made of aluminum which offers modest weight and reasonable strength. On the best bandsaws the tables are cast iron. This is more rigid than aluminum and the additional weight helps damp out any vibration from the machine’s motor.

Overall Size and Weight

A bandsaw’s size is usually defined by the diameter of its wheels. Don’t ask me why, that’s just how it is. At one end of the scale you might have a 9-inch bandsaw, whereas large workshop models can go to 24-inches, and industrial bandsaws can be even bigger. Don’t confuse wheel size with the maximum cut. They are not the same.

While most compact machines might not be truly portable bandsaws, they can be light enough to tuck under a bench or in a corner when not in use if your shop is small. If you have some dedicated space, it’s nice to upgrade from a benchtop bandsaw to one with a stand. This gives greater stability, and an optimal working height for most people. Pro-grade bandsaws usually have a stand built in. These can be superb tools but also need a lot of room. There are also weight considerations, so it’s important to check specifications carefully.

Power

You’ll generally find that small, beginner bandsaws are rated in amps, whereas larger models are rated in horsepower. If you’re going to be resawing large chunks of lumber on a regular basis you’ll want high performance, but I wouldn’t worry too much about the actual figures. Most well-known bandsaw brands are very good at matching the motor to the desired cutting capability.

Quality

Quality

If you’re buying a bandsaw online you won’t get hands-on until it arrives, so although you can return it if there’s a problem, I strongly suggest buying from one of the better-known brands. Even if you are a beginner, there’s a good chance you’ll have come across some of the names. This isn’t a comprehensive list but Ryobi, Skil, and WEN are popular budget bandsaws. JET, Laguna, Rikon, and Powermatic cover mid- to high-end models. If you’re not sure, check online for reviews. Any good brand will come up often, while lesser-known imports will hardly get a mention.

Bandsaw Safety And Maintenance

Anything that can slice through wood in seconds can make a real mess of your fingers! Bandsaws are actually pretty safe, but like any power tool can be dangerous if not used properly. Use a push stick to avoid getting your fingers near the blade. Make sure the bandsaw is unplugged when you’re changing blades, and wear sturdy gloves. Those steel bands are like a spring with teeth. It’s easy to catch yourself so be very careful. As with any woodworking, always wear safety glasses and a dust mask.

Bandsaw maintenance isn’t difficult, and following the instructions in your owner’s manual will keep the tool running smoothly and accurately for longer. A lot of dust gets trapped behind the doors that cover the wheels, so you’ll want to open them and clean that out regularly. A shopvac (like the one I mentioned in the article on apartment woodworking) is ideal.

I don’t think anybody really likes changing blades, but a blunt one can ruin your work, and if you leave it too long there’s a danger it might break. It’s not common, but it happens, and although not necessarily dangerous it will definitely give you a scare! A well set-up bandsaw should cut smoothly and easily. If you’re forcing the wood through the blade there’s something wrong and it’s probably that the blade is blunt.

I see questions from time to time about bandsaw blade sharpening. It’s not easy to find someone to do it, and even then I’m not sure it’s worth it. New blades for smaller models are around $10 to $15, and even those for large bandsaws seldom exceed $30. I just buy new, and put the old one in the recycling.

Best Bandsaws: My Top 3

Generally speaking I would suggest buying the best bandsaw you can afford. If you undersize you could end up being disappointed. That said, I understand people have different budgets so I’ve tried to choose 3 examples of what I believe are good value bandsaws at different price points.

First off is the Skil 9-Inch Bandsaw. You can get it on Amazon for about $230.00. Table size is 11-4/5” x 11-4/5”. Maximum width of cut is 9” and maximum depth of cut is 3-1/2”.

First off is the Skil 9-Inch Bandsaw. You can get it on Amazon for about $230.00. Table size is 11-4/5” x 11-4/5”. Maximum width of cut is 9” and maximum depth of cut is 3-1/2”.

This is a compact bandsaw with a lot of nice features. Blade tension is important on bandsaws so you want it to be easy to adjust. The Skil is much like other bandsaws with a winder on top, this one folds down when not in use. A blade tracking site window helps make setting it up a breeze.

Rack and pinion table adjustment is a real bonus on a cheap bandsaw and there are also 2 speeds. While this is a feature that’s not common on low-cost bandsaws I’m not sure it adds a lot of value. Myself, and most woodworkers I know, just leave their bandsaw on the fastest setting anyway. Still, all-in-all it’s a good little benchtop bandsaw for the money.

Next up is the WEN 10-Inch Bandsaw and Stand available at Amazon for about $315.00. Table size is 14-1/8” x 12-1/2”. Maximum width of cut is 9-3/4” and maximum depth of cut is 6”.

Next up is the WEN 10-Inch Bandsaw and Stand available at Amazon for about $315.00. Table size is 14-1/8” x 12-1/2”. Maximum width of cut is 9-3/4” and maximum depth of cut is 6”.

I’m a fan of WEN power tools. Although they’re made in China the company is headquartered in West Dundee, Illinois, and they seem to work hard to combine value-for-money, durability, and reliability.

So what do you get for your extra $85 compared to the Skil? Well, it has larger cutting capacities, particularly the depth. There’s a more powerful motor, and personally I think the blade guides are better, which improves accuracy. There’s also a handy little worklight, and the stand of course. If I was looking for a beginner bandsaw, and I wasn’t cramped for space, this is the one I would choose.

My third pick is the JET 14-Inch Bandsaw available from Woodcraft for $999.00. That’s a sale price, so it might have gone up a bit by the time you read this. Table size is 15” x 15”. Maximum width of cut is 13-1/2″ and maximum depth of cut is 6”.

My third pick is the JET 14-Inch Bandsaw available from Woodcraft for $999.00. That’s a sale price, so it might have gone up a bit by the time you read this. Table size is 15” x 15”. Maximum width of cut is 13-1/2″ and maximum depth of cut is 6”.

So maximum width is up compared to the WEN, but maximum depth is the same. In fact you won’t find many entry-level to mid-range bandsaws that exceed 6-inches. The table is a good bit larger, and cast iron rather than aluminum. It’s very rigid and hardwearing. Wheels are computer-balanced for smooth running and minimal vibration. Blade guides are impregnated with graphite so they also run smoothly. They don’t heat up the blade either so it stays sharper for longer. The bandsaw is bolted to a sturdy stand giving it great stability.

I would call this a professional-quality bandsaw. A worthwhile investment if you’re going to spend a lot of time in the shop. Bear in mind it weighs nearly 200 pounds so there could be a shipping charge.

So those are my top three, from budget bandsaw to pro. Just so you’ve got a full picture I’ll leave you with a link to a high-end 24-Inch Powermatic. It’s a beauty but you’ll need deep pockets!

If you have any qestions or comments, as always drop me a note.

Main photo by Cottonbro Studio: Prices correct at the time of publication.